Volume 30, Number 8—August 2024

Research Letter

Persistence of Influenza H5N1 and H1N1 Viruses in Unpasteurized Milk on Milking Unit Surfaces

Figure 1

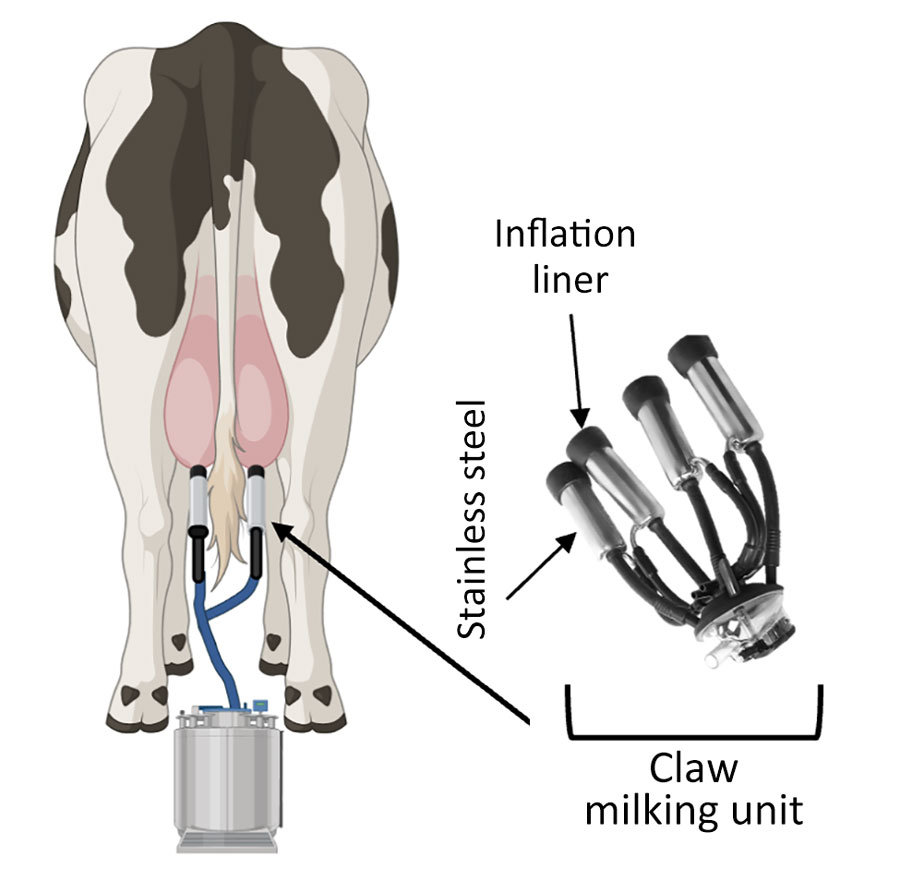

Figure 1. Illustration of milking unit surfaces tested in a study of persistence of influenza H5N1 and H1N1 viruses in unpasteurized milk. Before attaching the milking unit (claw), a dairy worker disinfects the teat ends, performs forestripping of each teat to detect abnormal milk, and then wipes each teat with a clean dry towel. Workers then attach the milking unit to the cow teats. A pulsation system opens and closes the rubber inflation liner (at left) around the teat to massage it, mimicking a human stripping action. A vacuum pump is controlled by a variable speed drive and adjusts the suction to allow milk to flow down a pipeline away from the cow into a bulk tank or directly onto a truck. Additional sources of exposure to humans include handling of raw unpasteurized milk collected separately from sick cows or during the pasteurization process. Schematic created in BioRender (https://www.biorender.com).

1These first authors contributed equally to this article.